SYNERBOT CB SERIES.

WELDING UNITS WITH COLLABORATIVE ROBOT

We present a new range of MIG/MAG welding units automated by Collaborative Robot. This new product line allows manufacturers to break the barrier that prevents the implementation of new robotization technologies that increase the productivity of the welding processes that are currently being carried out manually.

To break this barrier we offer a product and service pack that allows:

- Lose the fear of Robotics by offering simplicity, security and technical support.

- Seamlessly integrate the Unit into the production area. CE marking.

- Ease of programming and use.

If you want to download the brochure fill in the following information

STANDARD UNIT PACKS WITH COLLABORATIVE ROBOT UR5 / UR10.

SynerBot 4000 DW-CB UR5/UR10.

Modular pulsed synergic welding equipment of 400 A.

Water-cooled welding torch.

SynerBot 4000 CW- CB UR5/UR10.

Compact 400 A pulsed synergic welding equipment.

Water-cooled welding torch.

SynerBot 4000 CS- CB UR5/UR10.

Compact 400 A pulsed synergic welding equipment.

Dry welding torch.

Advantages of implementing these units in the production area:

- Productivity increases much higher than those obtained with manual cell operation.

- Resultados independientes de soldador. Repetitividad de proceso garantizada.

- Unidad automatizada con robot colaborativo de fácil integración y cumplimiento CE.

- Facilidad de programación. Tecnología de soldadura (URCap) certificado por Universal Robots.

- Facilidad de mantenimiento y revisiones.

- Curso de formación máquina-Robot incluidos. Entrenamiento a operarios garantizado.

- Integración en planta de gran facilidad con periodo de adaptación extremadamente corto.

WELDING EQUIPMENT.

In these robotic units, the heart of the welding starts from a pulsed synergic control inverter power source. These teams have implemented the Welding Technology which has been carefully developed by our R&D department in collaboration with the best master welders.. There our best Synergia has been produced. Master welding of steels, stainless steels and aluminum thanks to 83 application programs (master programs). The regulation and synergic programming is very simple, which makes them great welding masters.

SynerBot 4000 DW

- Power 3Ph-400 V

- I2 max= 400 A

- Independent wire feeder

- Cooled torch system

- Standard and pulsed arc

- Bilevel and bipulse modes

- 83 master programs

- 99 user programs

SynerBot 4000 CW

- Power 3Ph-400 V

- I2 max= 400 A

- Compact equipment

- Cooled torch system

- Standard and pulsed arc

- Bilevel and bipulse modes

- 83 master programs

- 99 user programs

SynerBot 4000 CS

- Power 3Ph-400 V

- I2 max= 400 A

- Compact equipment

- Dry torch system

- Standard and pulsed arc

- Bilevel and bipulse modes

- 83 master programs

- 99 user programs

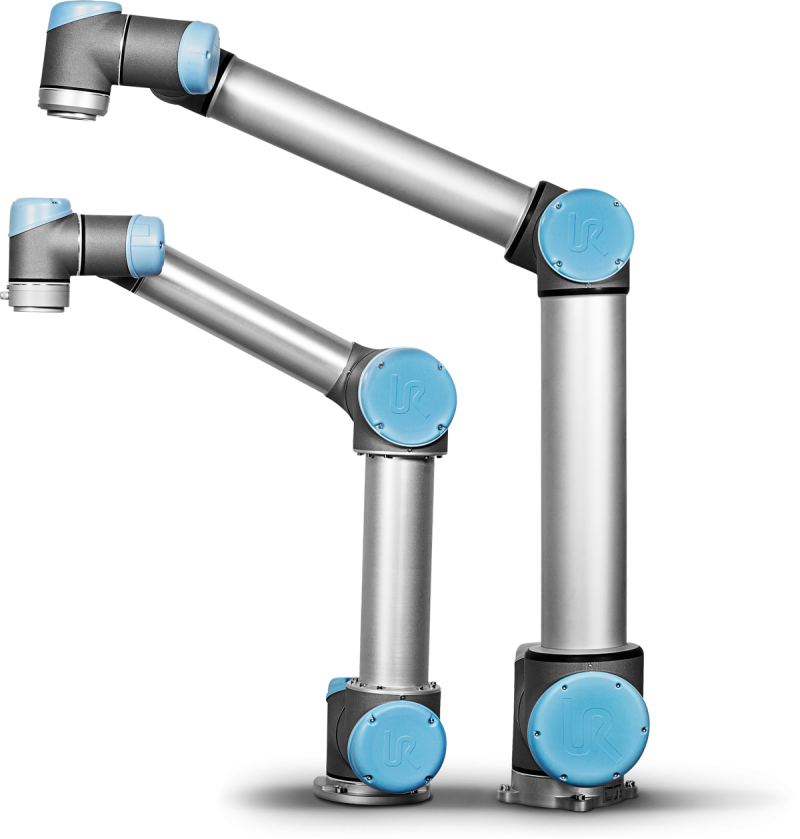

COLLABORATIVE ROBOT.

Collaborative robots from Universal Robots are programmed using a highly intuitive graphical touch interface. It does not have the complexity of industrial robotics to use. That is why we have developed SynerBot CB series , a solution that allows the jump to robotic welding with great ease.

FEATURES

Light and easily transportable, allowing its use as an alternate in different applications and positions and making it ideal even for medium and short series.

Programming console based on a large and very intuitive touch screen.

Its intrinsically safe design makes it easy to design safe cells.

| Robot type | UR5 | UR10 |

|---|---|---|

| Max. payload | 5 kg | 10 kg |

| Reach | 850 mm | 1.300 mm |

| Joint range | ±360° each joint | ±360° each joint |

| Max. joint speed | 180°/s | Base and shoulder: 120°/s Rest: 180°/s |

| Max. tool speed | Approx. 1 m/s | Approx. 1 m/s |

| Repeatability | ±0,1 mm | ±0,1 mm |

| Degrees of freedom | 6 rotary joints | 6 rotary joints |

| Control box I/O port | 16 digital inputs, 16 digital outputs, 2 anallog inputs, 2 analog outputs. | 16 digital inputs, 16 digital outputs, 2 anallog inputs, 2 analog outputs. |

| Communication | TCP/IP 100 Mbit: IEEE 802.3u, 100BASE-TX Ethernet socket, modbus TCP & EtherNet/IP adapter, Profinet. | TCP/IP 100 Mbit: IEEE 802.3u, 100BASE-TX Ethernet socket, modbus TCP & EtherNet/IP adapter, Profinet. |

| Collaborative operation | 15 advanced security features. In accordance with: EN ISO 13849-1:2008, PLd and EN ISO 10218-1:2011, clause 5.10.5. | 15 advanced security features. In accordance with: EN ISO 13849-1:2008, PLd and EN ISO 10218-1:2011, clause 5.10.5. |

| Power supply | 100-240 VAC, 50-60 Hz. | 100-240 VAC, 50-60 Hz. |

| Programming | PolyScope graphical user interface on 12” touch screen. | PolyScope graphical user interface on 12” touch screen. |

Accessories

Freedrive pedal

Protective covers

Synerbot control disc CD-2S

URCap.

WELDING TECHNOLOGY

The URCap Synerbot Welding Technology has been developed by Gala Gar to integrate all welding technology into collaborative UR robots, making welding robotization fast and easy.

Characteristics

- Spot Welding Node for welding spots

- Seam Welding Node for welding seams

- Waypoints for welding seams. Three types: WP Continuous, WP With Stop, WP Circular

- Installation screen

- Signal management during stops and emergencies

- Indication of missing data or possible errors

Its intuitive interface and the welding process outline. They guarantee that the welders of each company in which our technology has been integrated, can carry out their work masterfully.

Furthermore, we always include a complete training package in our installations. With this trsining, your crew will be perfectly autonomous.

Our URCap is currently available in English, Spanish and French.

Accessories

Protective rubber frame for Programming Console

Protection glass for touch screen

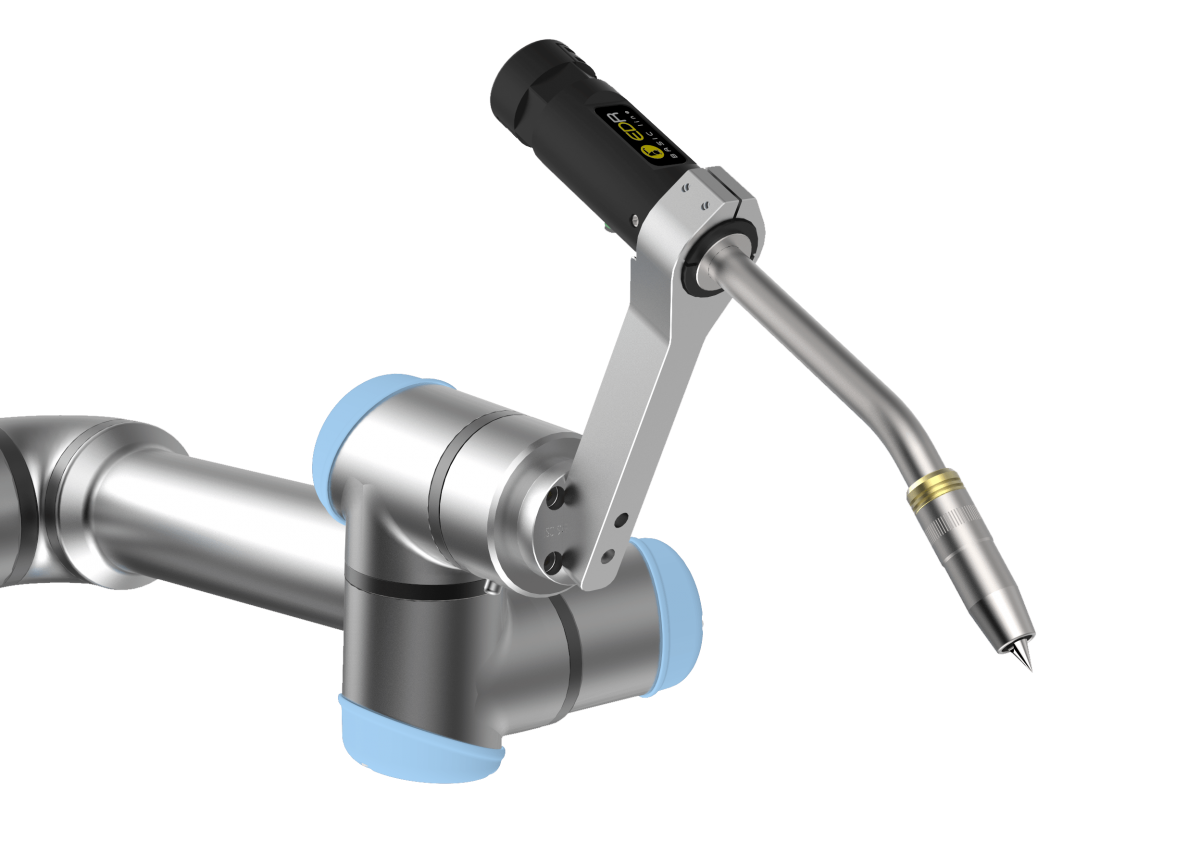

eBasic welding

torches.

Torches designed for welding solutions with collaborative robots. This line of eBASIC torches adapts perfectly to all the demands of collaborative robots due to its low weight and great functionality.

Robust and light necks calibrated to maintain a stable TCP during the life of the torch, as well as a stainless steel structure that gives excellent rigidity and prevents temperature increases in the back areas of the neck, and can be handled more easily .

Ebasic 42G: Dry torch 250 A /60%.

EBasic 52W: Water cooled torch. 400 A /100 %

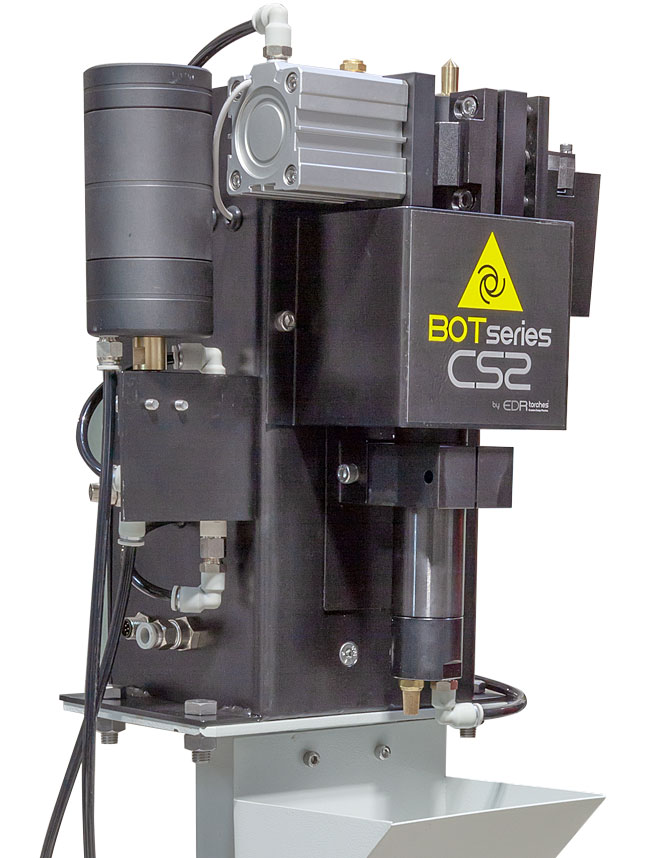

Cleaning station

CS2.

Automated cleaning system for welding robot cells, the system eliminates projections automatically without the need for the welding cell.

Tres fases de operación: Fresado de tobera, corte de hilo de soldadura y pulverización con spray antiproyecciones.

Garantiza continuidad del proceso de soldadura manteniendo libre de escoria y proyecciones la tobera de la antorcha de soldadura.

Ventajas de la Estación de limpieza CS2.

- Cortes de hilo automático.

- Cambio rápido de fresas de limpieza.

- Sistema de rociado de líquido anti-proyecciones.

- Secuencia programada desde el robot de soldadura mediante entradas de PLC.

- Fácil instalación.

- Regulación de fuerza de la rotación de la fresa.

Operation Control.

This industrial control brings together all the necessary controls in a single panel for comfortable and efficient programming and operation.

It controls the program start and stop functions, emergency mushroom, machine error reset, simulation mode for welding and machine parameter release, in addition to two free-use buttons.

SYNERBOT CB SERIES Standard units.

| Description | Synerbot 4000 CS UR10 | Synerbot 4000 CS UR10 |

|---|---|---|

| Reference | R061110 | |

| Power Source | GPS 4000 DR | |

| Cooling module | – | |

| Transport trolley | 64184000 | |

| Wire feeder | – | |

| Energetic package | 64189006 | |

| Robot connection interface | IR-5000 | |

| UR10 collaborative robot | R061000 | |

| UR10 Robot protective suit | R061001 | |

| Teach pendant protection rubber frame | Optional | |

| Teach pendant screen protector | Optional | |

| Industrial operatio control /pedal | R069002 | |

| Full welding torch with flange | EDR 510 |

EXPERTS IN ROBOTIC WELDING.

Our technical support will provide help and information on robotic welding.